PRODUCT

PRODUCT

LATEST NEWS

CONTACT US

Jiangsu headquarters add: No.388 Chuanjiang Road, Economic and Technological Development Zone, Yangzhou City, Jiangsu Province;

Beijing headquarters add: Building 19th in District 7th, No. 188 of South Fourth Ring Road, Fengtai District, Beijing City.

Denitration

Core technology of denitration

Denitration Technology Classification

■ Flue gas denitration technology

● Selective catalytic reduction (SCR)

● Selective non-catalytic reduction (SNCR)

● Technologies such as electron beam method and incandescence carbon reduction

● Low Nox combustion engineering

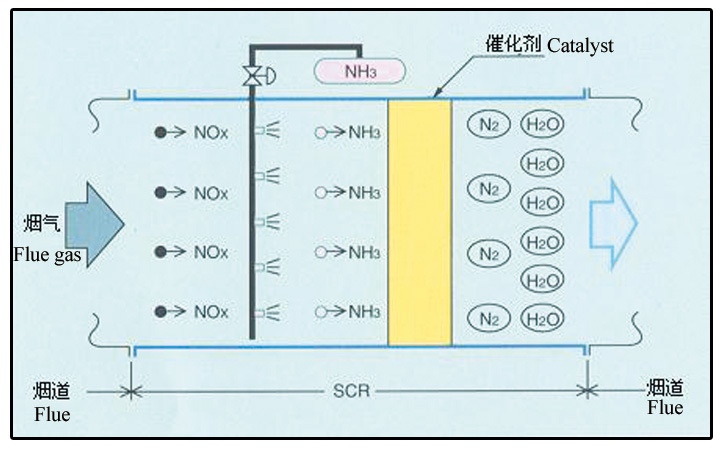

SCR (Selectivity catalyst reduction) is the relatively most mature and reliable denitration method at present. The flue gas denitration rate can reach more than 90%.When the required NOx desorption efficiency is more than 50%, SCR is the most effective boiler denitration technology recognized by the world.

Jiangsu Fengye Technology & Environment Group has been striving to develop SCR (Selective Catalytic Reduction, SCR) technology since 2005 and cooperates with world-renowned environmental protection companies to contract the general contract project of SCR engineering and actively carries out the independent research and development of SCR engineering technology at the same time.

The Group has mastered the technology of SCR engineering and will meet the owner’s requirement for the NOx discharge while ensuring the normal operation of boiler.

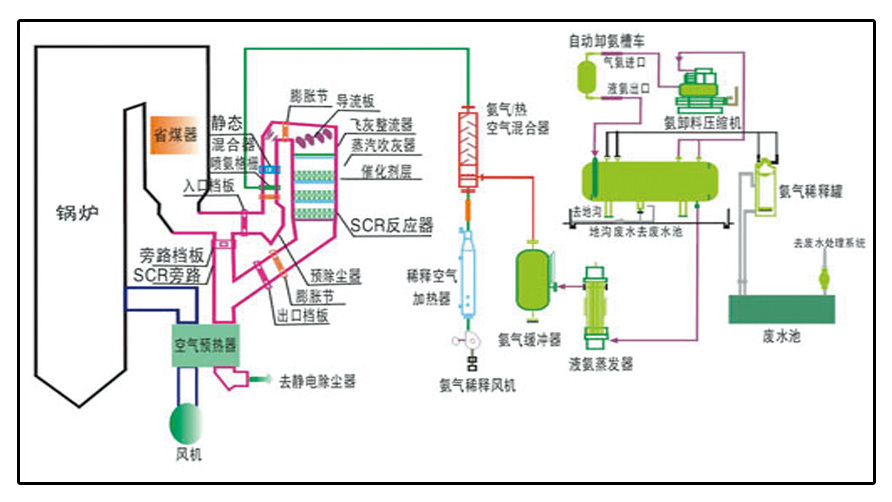

SCR System Flow

The Main Characteristics of Self-developed

Denitration Catalyst Technique

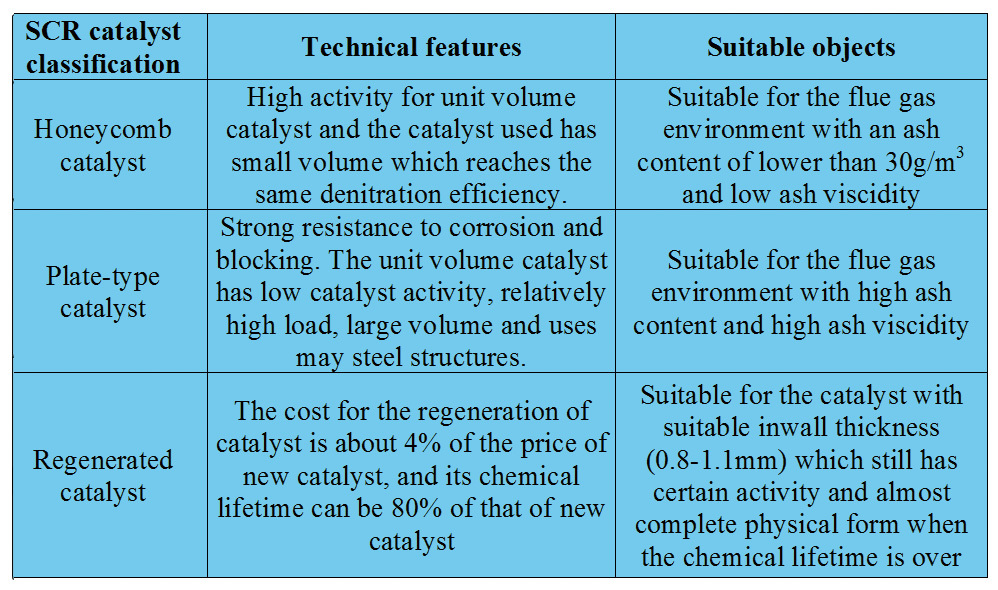

■ Choose appropriate catalysts for different projects (including honeycomb catalyst and plate-type catalyst, etc.);

■ Reduce the dust stratification on the catalyst through the optimization of catalyst parameters and maintain a lower drop of pressure of the smoke;

■ Effectively remove the large particles ash from the flue gas and prevent the large particles ash to block the catalyst;

■ Use sonic soot cleaning or steam soot blowing to effectively prevent or eliminate the soot formation on the catalyst;

■ Adopt physical modeling and digital simulation technology to elaborately design SCR system; effectively use the catalyst to minimum the ammonia consumption, reduce the soot formation and keep the flue gas pressure drop of SCR system at a low level.

■ The design of reactor has good applicability convenient for the installation of catalyst;

■ The procedure parameter is controlled automatically and the ammonia injection amount can be controlled according to the owner’s requirements;

■ Fully optimize the steel frame of SCR area to ensure the safety of SCR reactor;

■ The design of ammonia area meet the national and industrial standards and is safe and reliable.

Sketch Map for the Reaction Principle of SCR Denitration Technology

Core Technology of Denitration Catalyst

Jiangsu Fengye Technology & Environment Group Corporation Limited spares no efforts in the thermal power generation environmental-friendly industry, established SCR catalyst associated research and development center with North China Electric Power University and built professional academician workstation. The high-technology honeycomb ceramic denitration catalyst products of the thermal power plant was developed at February, 2010 through the unremitting efforts made by the scientific research personnel of both sides and by drawing on the experience of the advanced technology of the same kind of Japan, Germany and South Korea. After the detection, we found that each parameter and performance index of such product is equal or exceed that of foreign like products, and our company becomes the first environmental protection company owning the proprietary intellectual property rights of SCR catalyst in China. And our company developed SCR plate-type catalyst and regenerated catalyst technology and products with independent intellectual property through the associated research and development with North China Electric Power University and Zhejiang University, and the industrialization was fully formed in 2013.

From 2014, a total capacity for SCR catalyst of 60000m3 has formed, including 25000m3 honeycomb catalyst, 20000m3 plate-type catalyst and 20000 m3 regenerated catalyst with a general income of RMB 2 billion and taxation of profit of RMB 0.3-0.4 billion. Our company is the world largest environmental core product research and production enterprise that deal with product research and production, waste catalyst treatment and raw material recycle for different customers of the world and different types of coal and can meet different requirements.