PRODUCT

PRODUCT

LATEST NEWS

CONTACT US

Jiangsu headquarters add: No.388 Chuanjiang Road, Economic and Technological Development Zone, Yangzhou City, Jiangsu Province;

Beijing headquarters add: Building 19th in District 7th, No. 188 of South Fourth Ring Road, Fengtai District, Beijing City.

Honeycomb

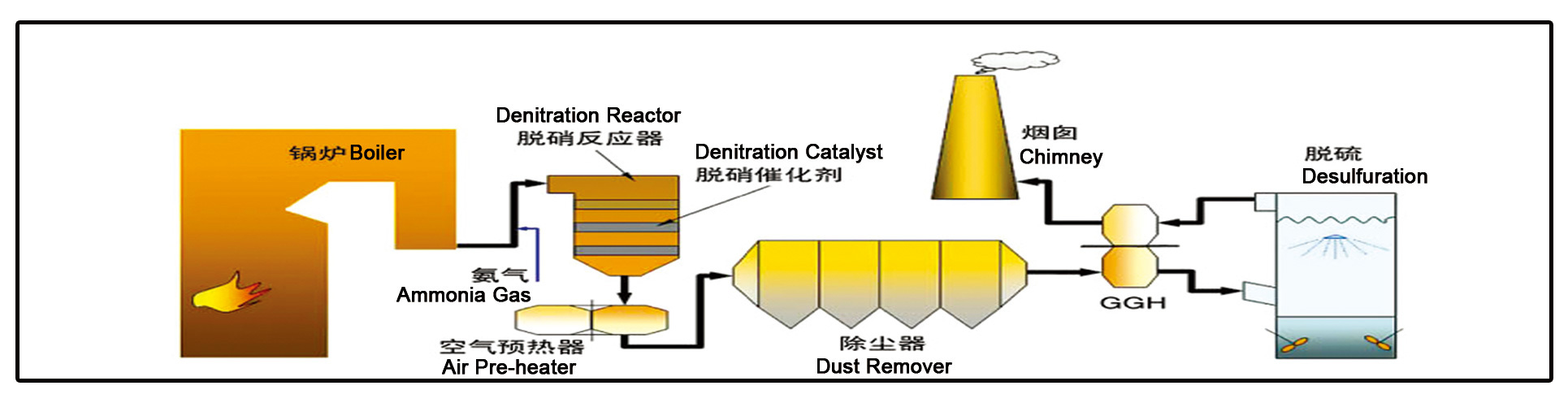

SCR Denitration Technology

SCR Denitration Technology is most prevailing one for coal-fired boiler flue gas, with denitration rate over 95%. The choice and deign of catalysts are crucial to ensure SCR denitration system to operate efficiently, steadily and constantly. Its technical formula, assessment software and production process are cardinal part of our patent.

SCR Process for Combustion Units

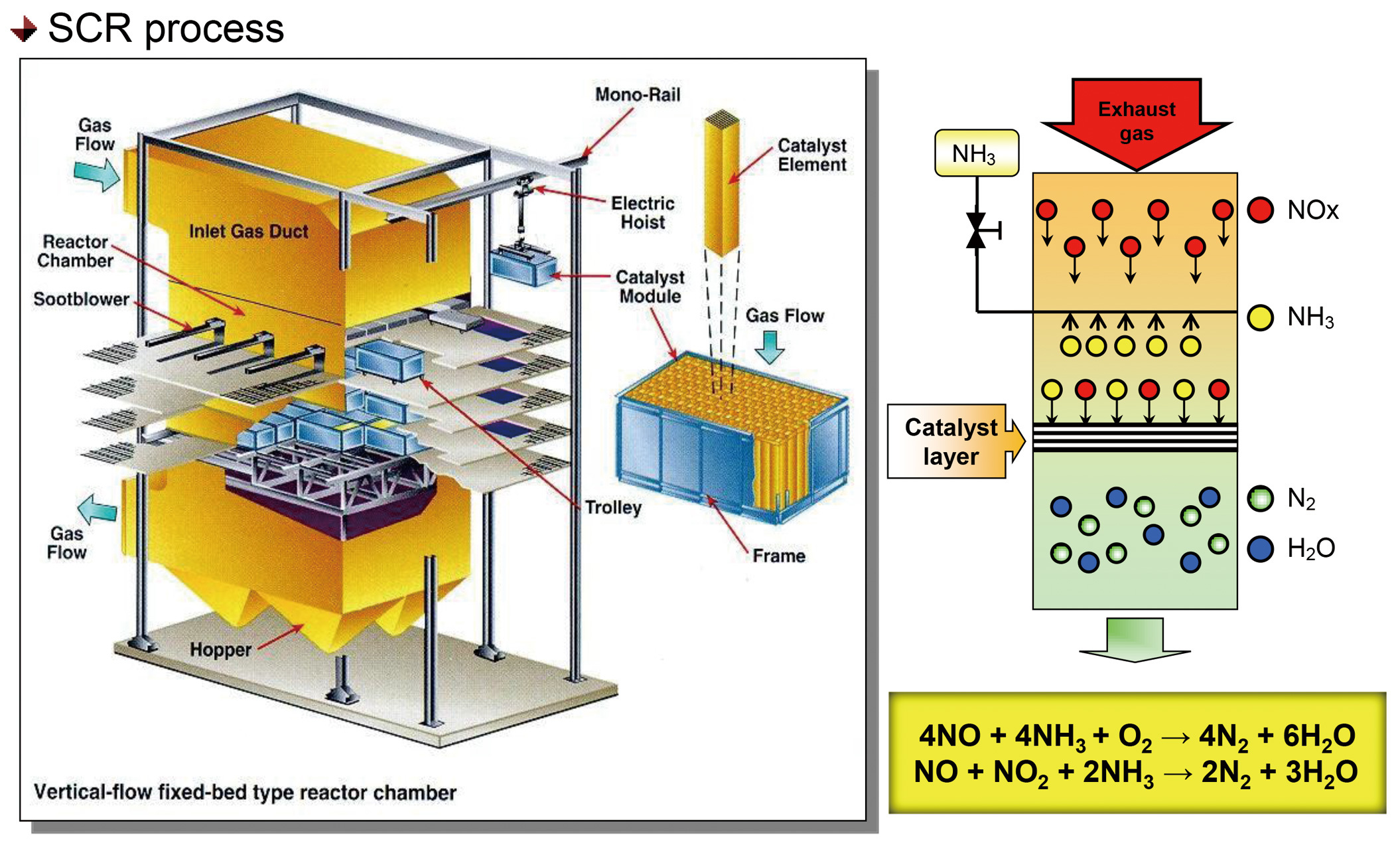

Selective Catalytic Reduction (SCR)

Advantages of Self-owned Brand:

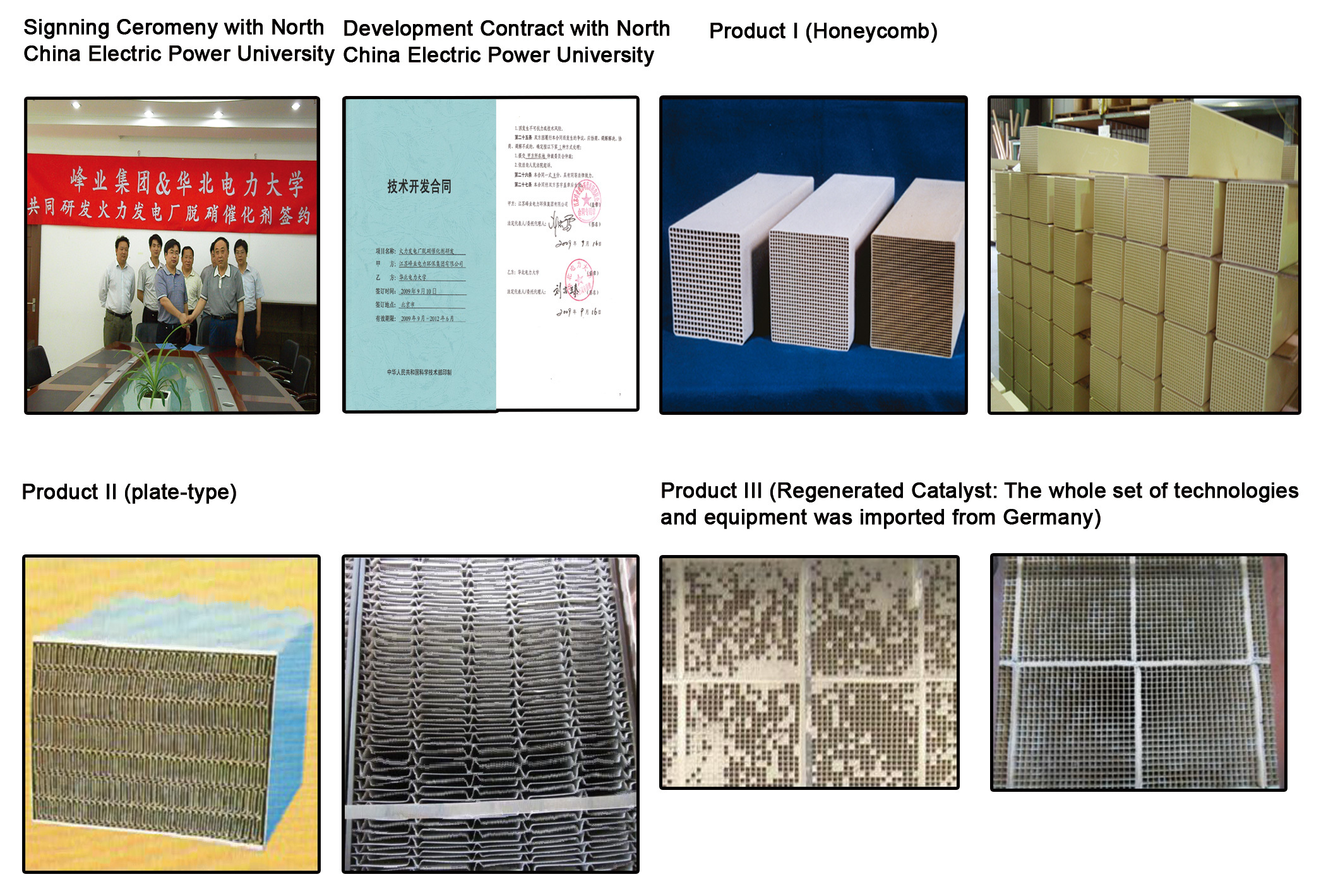

With three years in research and development and reference to production processes and technologies of other countries, like Japan, U.S., Germany and Korea, Wande has successfully developed both honeycomb and plate-type ceramic catalysts which are the most advanced and the most suitable products for denitration of coal fired boilers of thermal power plants in China. Parameters and performance indicators of these products were proved to parallel or surpass their foreign counterparts. Wande holds independent IPR for these products, filling up China’s blank in development and production of catalysts of these types.

Advantages of Wande SCR Catalysts:

1. Wande SCR catalysts enjoys some merits of performance, including high-activity, high denitration rate, high specific surface area, low SO2 conversion rate, and low NH3 escape rate. Meanwhile, they are extraordinary in terms of machinery performance, resistance to high pressure, shock, and poisoning. Wande SCR catalysts are well adapted to various types of coal used and different working conditions in thermal power plants in China.

2. Compared with domestic products, Wande SCR catalysts are more suitable for the complex working condition of boiler flue gas under high temperature and pressure and dusty circumstance. They are also geared to the specific working condition of hybrid coal-gas fired power plants.

◆ State of the art Production Process:

Inspired by advanced production line in other countries, Wande independently developed SCR catalyst production process and technology. For key equipment, Wande imported high speed mixing rolls from Nippon Eirich Co., Ltd., and vacuum-extruders from Miyazaki Machinery System, which fundamentally ensure the performance and quality of Wande products.

◆ Most Reliable Manufacturing Process:

Wande has quality management and control team, equipped with advanced idea and formulating rigid regulations. All members have over 5 years of management experience for SCR ceramic honeycomb catalyst production and expertise.

All Wande employees engaged in production majored in ceramics manufacturing, with above junior college degree and vocational training of at least 6 months. Their education background and professionalism assure product qualification ratio above 98%, which considerably reduce the cost, and enhance the competitiveness of Wande products.

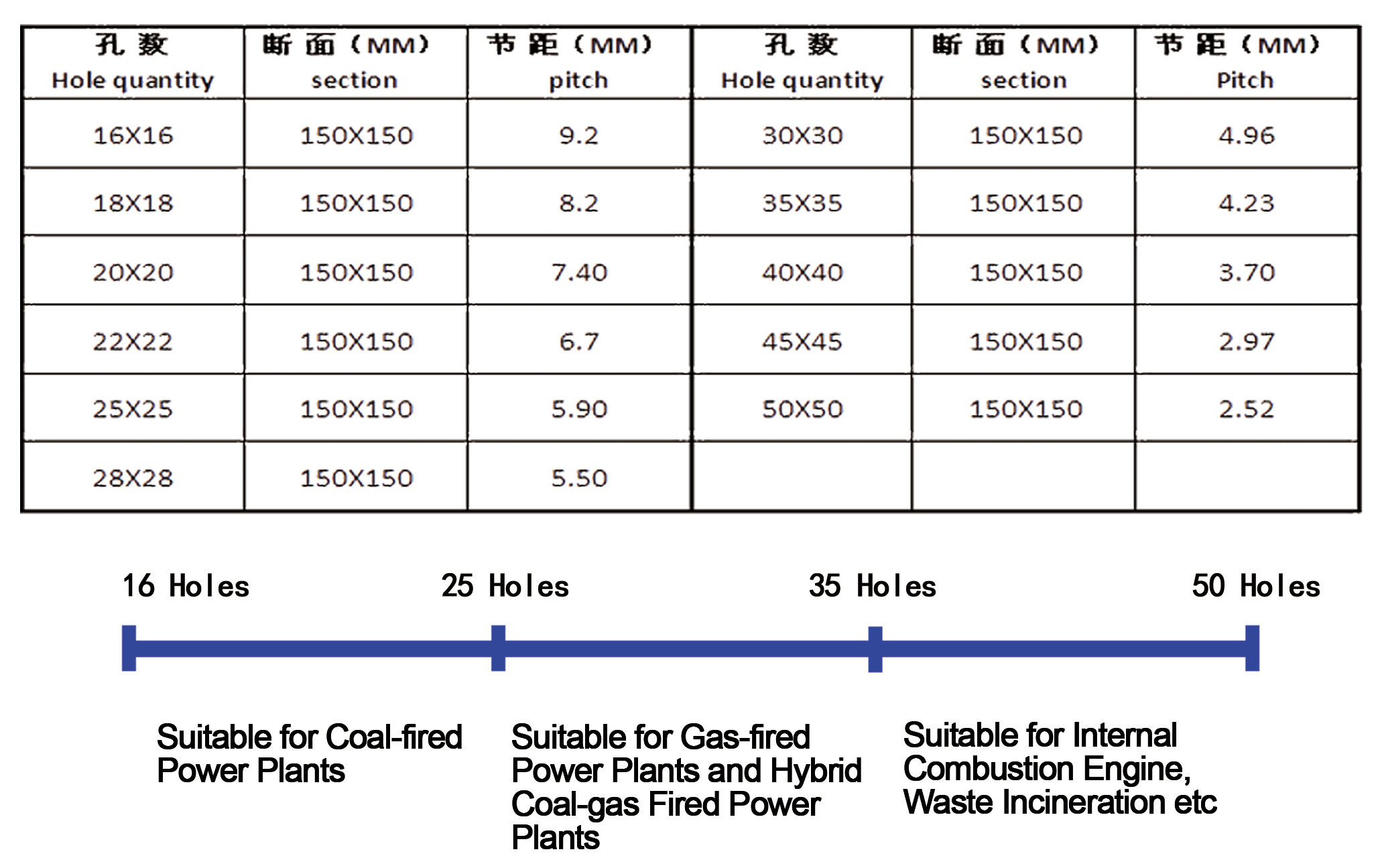

◆ Types and Parameters of Catalysts